In the early morning, silence fills the rooms of Bldg. 2224. Machines lay still, and tools are neatly placed where they belong. The calm is quickly broken as members of the 86th Maintenance Squadron enter the metals shop and begin their workday.

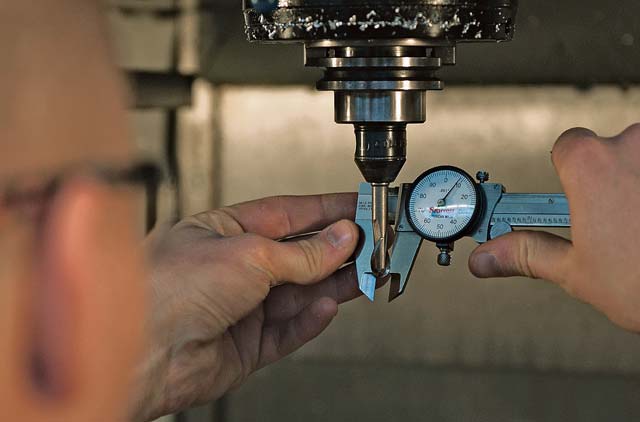

The metals fabrication shop is responsible for repairing metal parts on aircraft and ground equipment throughout Ramstein.

“We support aircraft and ground equipment by performing repairs on metal components,” said Senior Airman Isaiah Knorr, 86th MXS aircraft metals technology journeyman. “We machine and fabricate different parts for their equipment and perform welding repairs. We deal with just about anything involving metal.”

While the parts the metal shop fabricates can vary in sizes, the importance of their job is constant. Not being able to fix a part can mean the difference between mission success and failure, saving the Air Force money or costing thousands in new parts.

“We save the Air Force time and money by being able to get requirements for a part and design it,” said Tech. Sgt. Nathaniel Steinmetz, 86th MXS aircraft metals technology NCOIC. “If our job didn’t exist, it would cost a lot to contract out all the work we do. We also make the difference in a mission being held up by hours or days.”

For Airmen of the metals shop, knowing their job has an impact on the Air Force mission can give them satisfaction, but it’s not the only thing that makes them happy to come to work.

“It definitely feels good to come here and see all this big equipment and see everything you can do with it,” Knorr said. “When you come in and see what’s going on here on a busy day, with four machines going at the same time, metal chips flying everywhere, it really puts a smile on your face.

“A lot of jobs that I’ve worked in the past, you don’t really have something to show for it,” he added. “It feels really good knowing you have something to represent your day’s work.”

Whether it’s the buzzing of a saw or the hissing of a welder, as long as there’s an aircraft in need of a part, the 86th MXS aircraft metals technology shop will be filled by the sound of hard work, repairing and replacing Ramstein’s equipment, one piece at a time.