The 86th Maintenance Squadron nondestructive inspection lab is in many ways similar to the services provided by a medical lab. They both use high-tech equipment to see things invisible to the naked eye and aid in preventive maintenance. Their goal is to keep the mission essentials healthy and in the fight.

The 86th MXS NDI lab is one of the most integral parts of the fabrication flight. The fabrication flight, as a team, is responsible for the detection and repair of any service or maintenance induced cracks and damage for all aircraft, aircraft subsystems and ground support equipment. The NDI lab ensures aircraft and related equipment are “Fit to Fight.”

“The detection and repair can be a daily struggle with today’s aging fleet and equipment,” said Tech. Sgt. Jeremy Cole, 86th MXS nondestructive inspection technician. “Ramstein, however, is lucky to have newer C-130J Super Hercules models, which have not accumulated the high flight hours of many other Air Force aircraft.”

Like X-ray examinations, preventive maintenance measure magnetic particle, and penetrant inspections determine if our planes are ready for takeoff.

The first step for an X-ray examination is to process the film. Using an automatic film processor, the image is developed, fixed, washed and dried, making it ready for viewing. Much like a medical X-ray examining bone fractures, NDI x-rays aircraft structures to pinpoint cracks in critical structures.

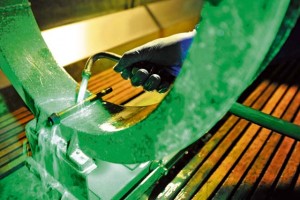

Fluorescent magnetic particle bath sprays tiny fluorescent magnetic particles over suspected damaged parts, preparing it for inspection. During magnetic particle inspection, specific parts are checked for structural integrity. When confirmed that no cracks exist, the part can be placed into service.

nondestructive inspection technician, performs a step in the penetrant inspection process, July 31 on Ramstein. This part in the process uses an emulsifying bath, which removes traces of excess penetrant, allowing crack indications to be more readily visible.

The penetrant inspection process uses an emulsifying bath, which removes traces of excess penetrant, allowing crack indications to be more visible. Any penetrant that seeps into the cracks will be visible due to its natural fluorescence under a black light.

Using a series of NDI inspections, it is possible to extend an aircraft’s life another 50 to 60 years, saving the Air Force money and saving lives.

“Any defect that goes undetected can potentially cause a catastrophic failure,” said Tech. Sgt. Michael Brandon, 86th MXS nondestructive inspection craftsman. “It would not be safe for planes to fly if we didn’t perform certain inspections.”

The NDI lab keeps aircraft in the air with constant checkups and preventive measures to reduce the chance of an aircraft being totally grounded, keeping our fleet and Airmen in good health.